방적사 공장

Worsted Spinning Mill

We produce differentiated, high-quality materials through the use of top-quality raw materials and special processing in state-of-the-art spinning facilities. Hohae uses the finest raw wool such as 100% merino wool and superwash wool in its worsted spinning process, and produces/supplies more than 80 high-quality yarns, as well as special wool blended yarns, through special processing methods such as siro-fil.

Use of eco-friendly raw materials

Hohae Textile seeks only the world's finest raw materials and uses only eco-friendly, certified raw materials to create safer products for the human body as well as the most beneficial production environment for environmental conservation.

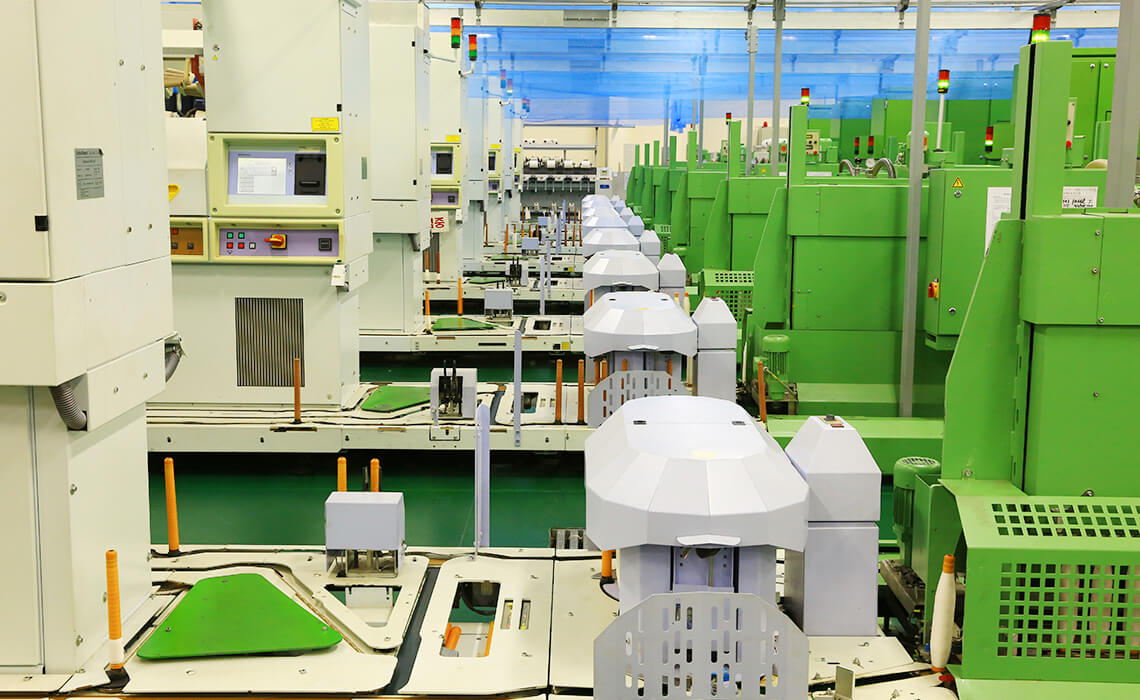

LTG air-conditioning system

With the introduction of the German LTG air-conditioning system, an active, automatic air-conditioning system is utilized to maintain temperature and humidity independently of each other between process lines. This creates an optimal production environment by preventing fly-in between production lines and adjusting temperature/humidity.

Human-friendly large spinning plant

We seek to maximize the safety of our employees and production efficiency by fully automating our production facilities and purifying the air from hazardous substances that may be released throughout the process with the latest air-conditioning facilities. We have built a large system that can produce up to 1,800 tons of high-quality weaving yarn and knitting yarn (raw white, dyed) annually.

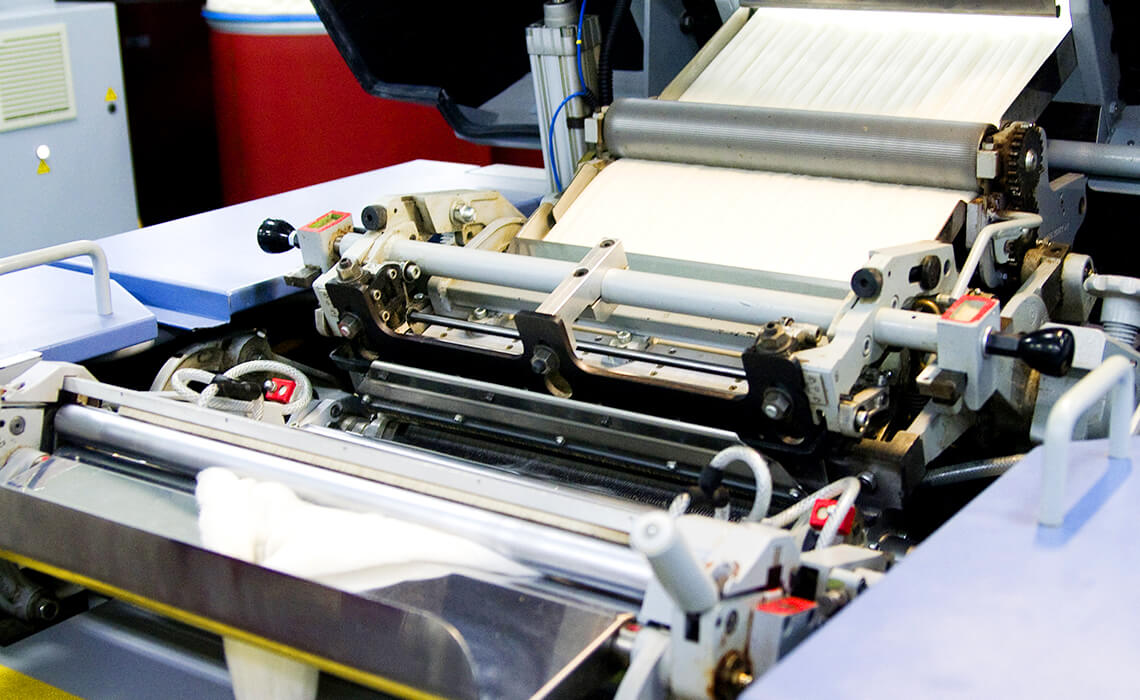

Equipped with state-of-the-art production equipment

We possess world-class production facilities that are comparable to any plant in the world by introducing state-of-the-art production facilities imported from France, Germany, Italy, and Japan. Hohae's system enables the optimal production efficiency and quality management required for worsted spinning production.